Jul 04,2025

Color masterbatch manufacturing process: technological upgrading drives green and efficient development of the industry

By Hefei Belief New Material Technology Co., Ltd. on 04/07/2025

Tags: color masterbatch | plastic |masterbatch

Color masterbatch manufacturing process: technological upgrading drives green and efficient development of the industry

As an indispensable "color engine" in modern industries such as plastics, chemical fibers, and coatings, the precision of its manufacturing process directly affects the performance and environmental performance of downstream products. The current industry is undergoing significant technological iterations, with a core focus on process optimization and material innovation.

Technological innovation: dual improvement of efficiency and accuracy

Mainstream process stability: The twin-screw extrusion process continues to dominate the industry due to its excellent mixing dispersion, high yield, and process controllability. Leading enterprises have significantly improved the uniformity of pigment dispersion and product stability, reducing defects such as "color spots", through screw combination optimization, precise temperature control segmentation, and vacuum devolatilization strengthening.

Intelligent empowerment: The introduction of automated batching systems and online quality monitoring (such as near-infrared spectroscopy) significantly reduces manual operation errors, achieves real-time tracking of production data and dynamic optimization of process parameters, and ensures consistency between batches.

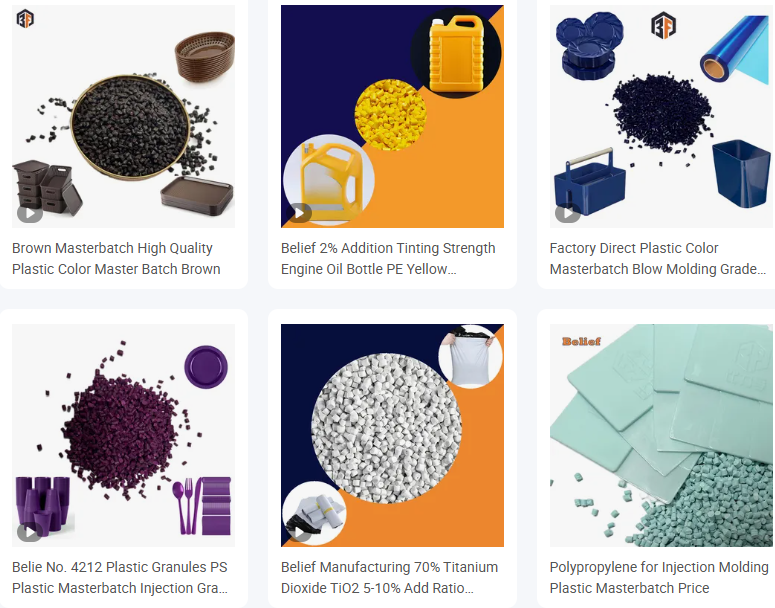

The image is sourced from Hefei Belief New Material Technology Co., Ltd.

Material Innovation: Balancing Environmental Protection and Functionality

Diversification of carrier resins: In order to meet the needs of different substrates, in addition to general polyolefin carriers, there is active development of specialized carriers suitable for engineering plastics (such as PA, PC) and biodegradable plastics (such as PLA, PBAT).

Green transformation acceleration: The tightening of environmental regulations promotes the use of heavy metal free pigments, high concentration formula design to reduce resin consumption, and the application of bio based/recyclable carrier resins as research and development hotspots, in response to the global "dual carbon" goal.

Functional integration: Masterbatch goes beyond a single coloring function and develops towards "one dose multi energy". The demand for masterbatch with composite functions such as UV resistance, flame retardancy, anti-static, and long-lasting antibacterial is rapidly increasing, adding value to downstream products.

Industry Trends and Challenges

Downstream demand driven trends such as lightweight packaging, plastic instead of steel in automobiles, and personalized home appliances have raised higher requirements for the weather resistance, migration, and processing adaptability of color masterbatch.

Sustainability pressure: Life cycle environmental assessment (LCA) is becoming increasingly important, driving companies to upgrade from raw material procurement, production processes to waste management towards green.

Concentration improvement: The increase in technological barriers has prompted the market to concentrate on top enterprises with research and development capabilities, economies of scale, and environmental compliance. According to the latest industry report, the global market size of color masterbatch is expected to exceed 20 billion US dollars by 2026, with a stable compound annual growth rate of over 5%.

conclusion

The manufacturing of color masterbatch is deeply evolving from traditional "coloring" functions to high-performance, multifunctional, green and sustainable directions. The core competitiveness lies in the refinement of processes, intelligence, and environmental innovation of materials. Only by continuously investing in technological research and development, embracing green and intelligent manufacturing, can enterprises win future growth space in the fierce market competition and increasingly strict environmental regulations. The collaborative innovation of the industrial chain will be a key driving force for promoting high-quality development of the industry.

The image is sourced from Hefei Belief New Material Technology Co., Ltd.

Recommended Products

More News

Jun 28,2025

Unraveling the Mysteries of Plastic Color Masterbatch

Jul 03,2024

What are the classifications of color masterbatch

Jul 28,2022

What is masterbatch? What is the main purpose of color masterbatch